Customer-specific matters

Every customer is different – and every sector has its own special requirements. For this reason, we are the ideal partner when it comes to special customer and product requests. Our engineers and technicians specialise in the continuous development of our existing range of products as well as the creation of new, customer-specific packaging materials.

Our very own in-house division for research & development, design, as well as mould, tool, and machine construction enables us to realise virtually any custom product request both quickly and cost-efficiently.

Design:

Developing a packaging product

Development example 1

Re-launch of a cap closure with integrated drinking cup

At the customer's request, a cap was designed with an integrated dosing aid. An emphasis was placed on creating a pleasing design in consultation with the customer. The closure consists of two parts. The existing TE1-18.282 was used as the basis for the tamper-evident closure. The drinking cap is an entirely new design. It is connected in a torque-proof manner with the tamper-evident closure via a permanent snap fit. Focus was also placed on straightforward machine processing.

The packaging was optimised in the following ways:

- New outer edge/fine fluting

- Drinking cup within the closure cap with rounded edges

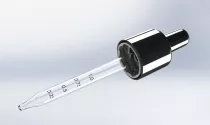

Development example 2

New packaging solution for e-cigarette liquids/K03-18.400

The customer was looking for a child-resistant packaging solution for e-liquids which allows for commonly encountered e-cigarettes to be filled safely and easily.

The packaging consists of three components: bottle, child-resistant and tamper-evident closure and cannula.

The closure design was created on the basis of the familiar push+turn principle and is additionally equipped with a tamper-evident feature. With the easily depressed cannula, all viscosities can be dosed. Filling the e-cigarette can be carried out with the easily depressible tip. The design of the long filling tip prevents the reservoir from being clogged during the filling procedure and generates pressure equalisation. The bottle label therefore remains in pristine condition, as the bottle no longer needs to be squeezed.

Development example 3

Tamper-evident closure with integrated drinking cup

Packaging for an oral hygiene solution. Dosing needed to be carried out directly in the closure cap. The closure also serves as a drinking cup.

(Previously: multi-part system which tended to leak.)

- Closure with reliable seal

- Drinking cup conveniently integrated

- Integrated injection-moulded tamper-evident seal

Complete solutions

We are glad to offer you complete solutions:

the perfect combination for your requirements.

BOTTLE | CLOSURE | DOSING SYSTEM

Describe your requirements to us – we will find you the perfect solution!